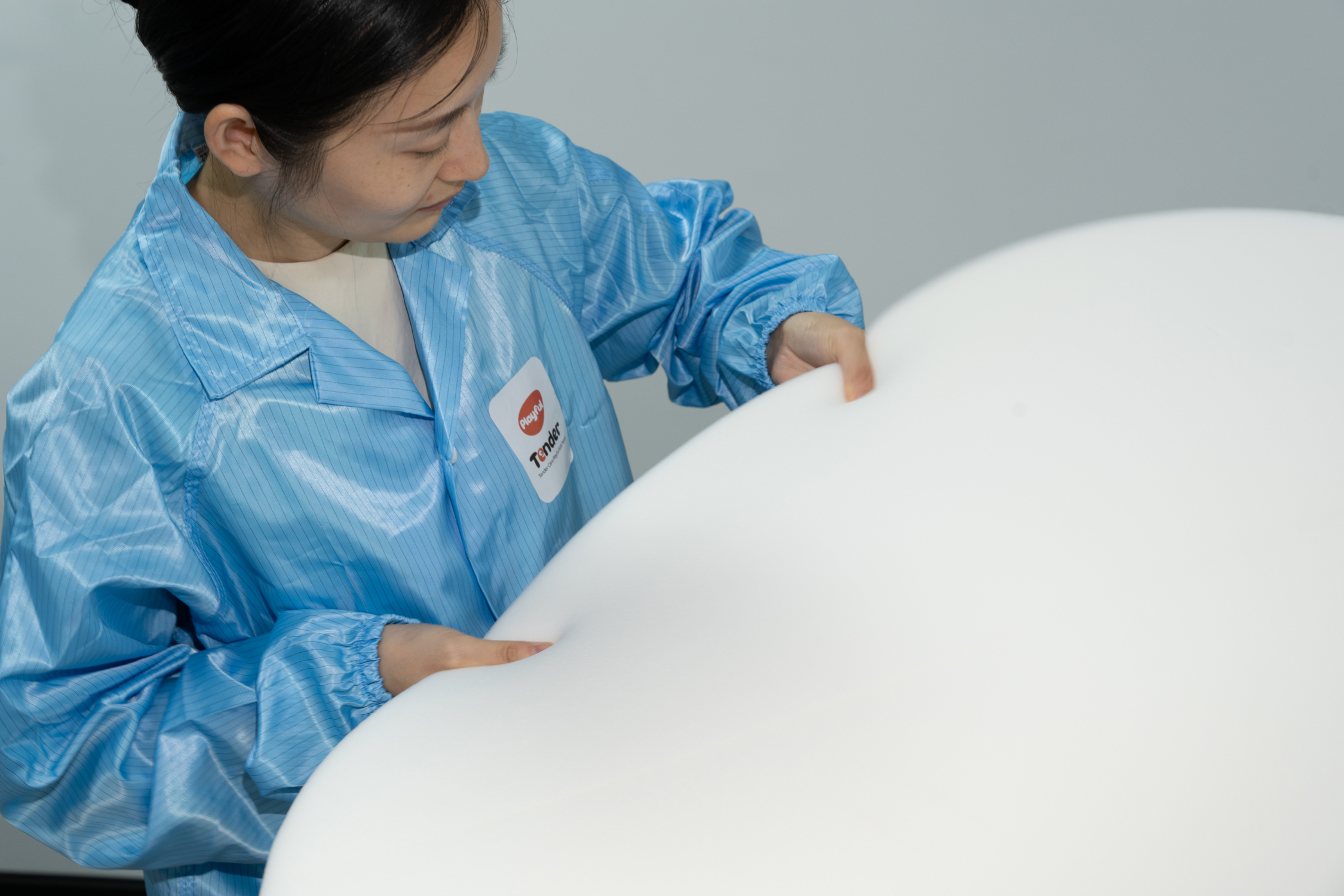

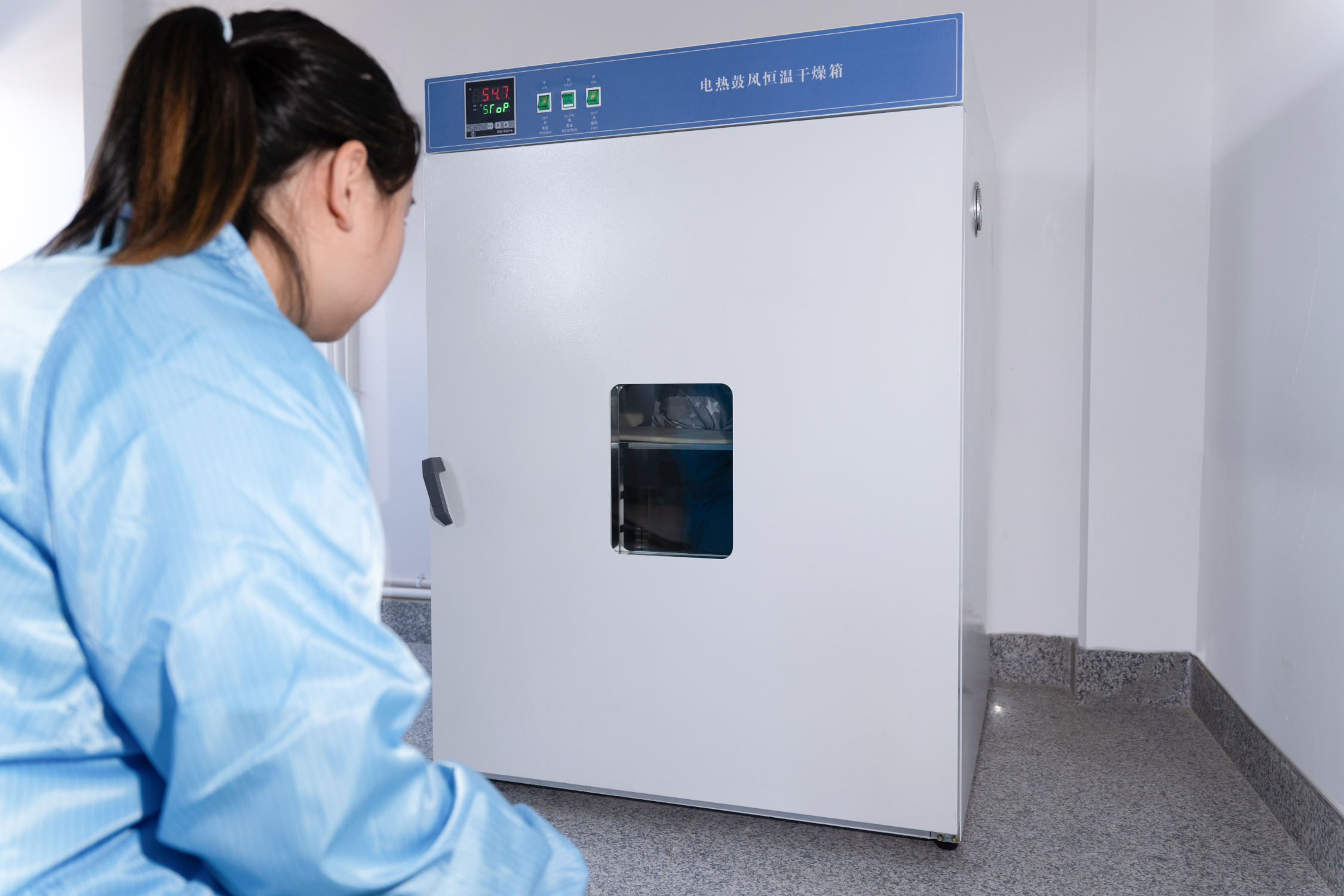

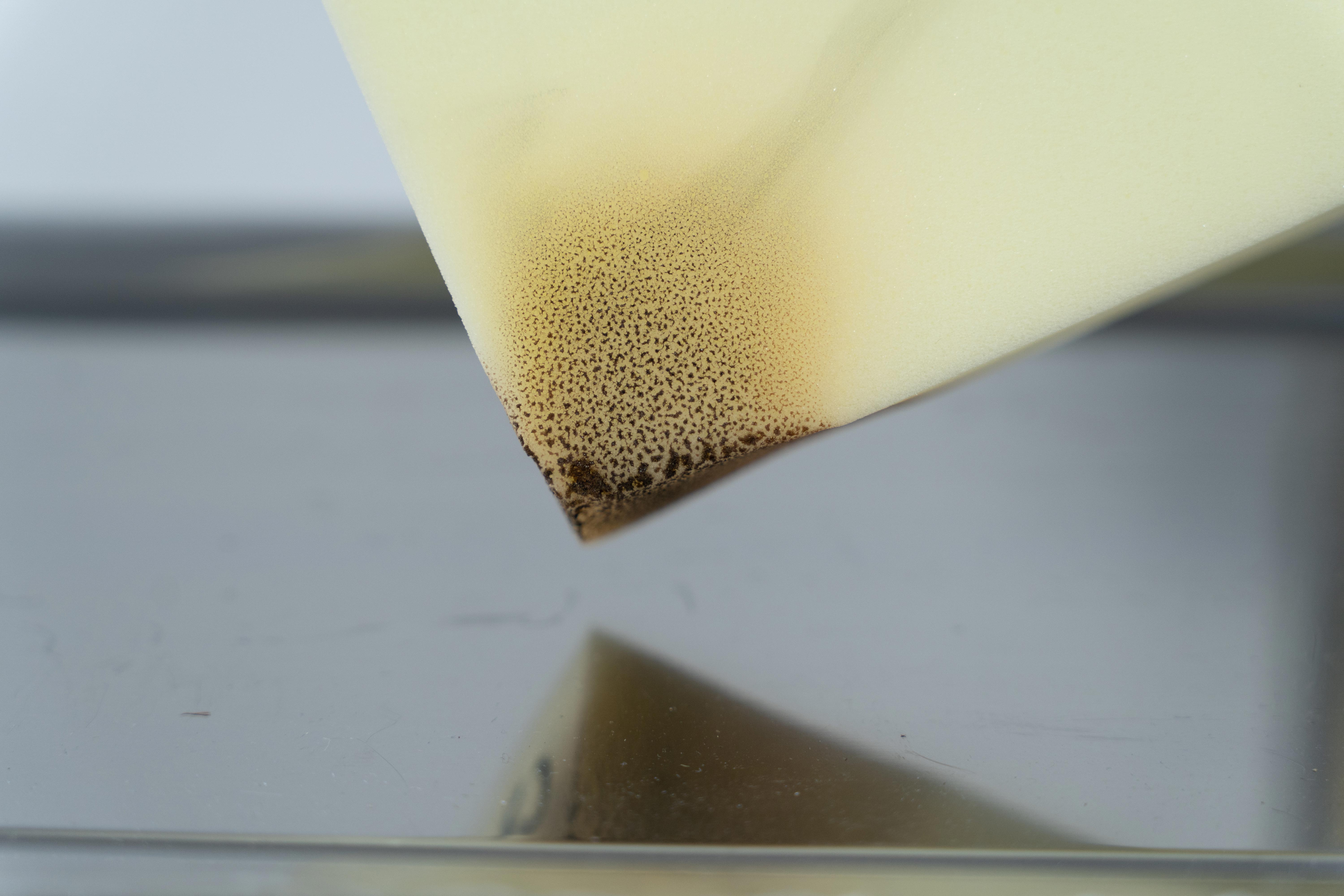

Fabric Color Inspection

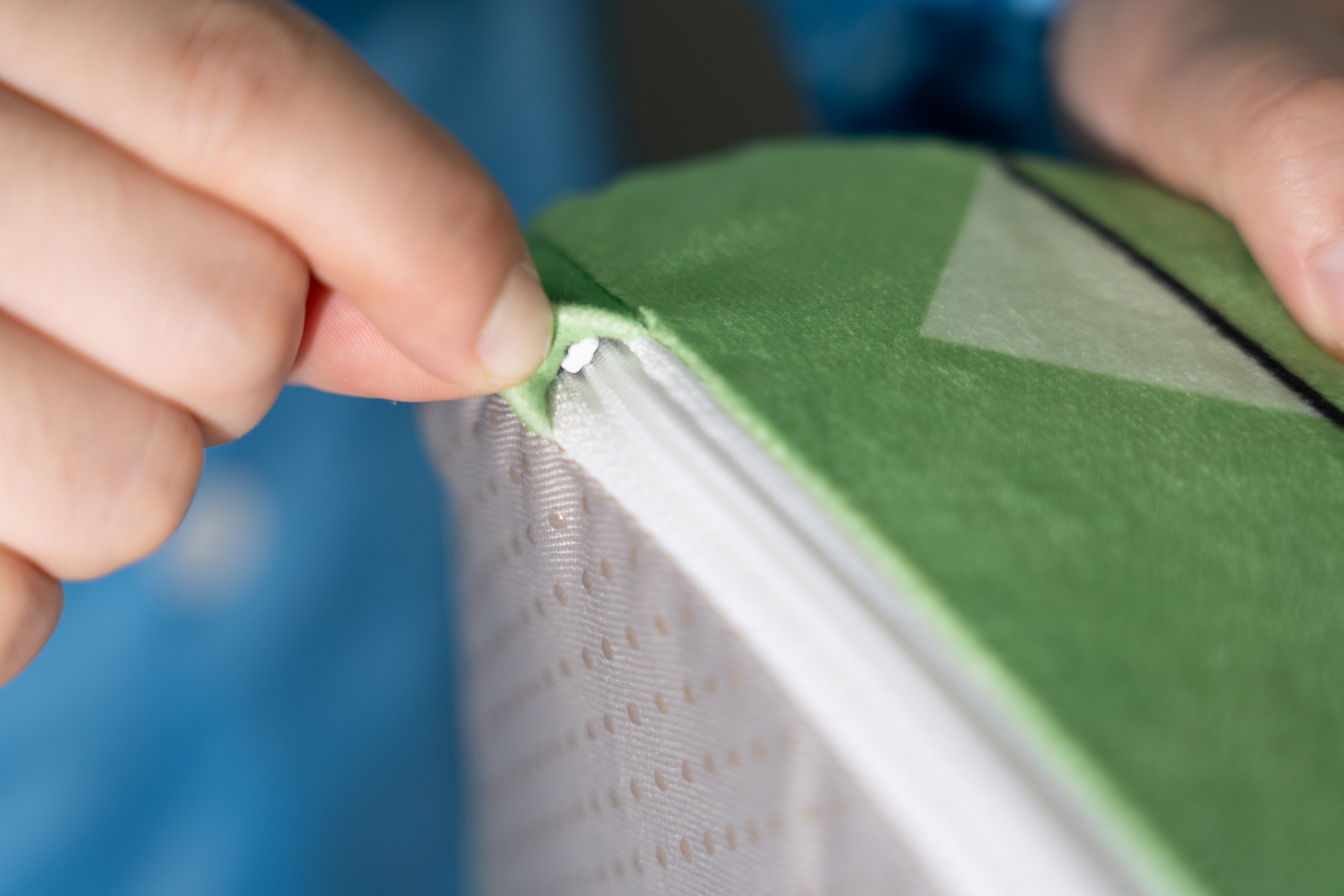

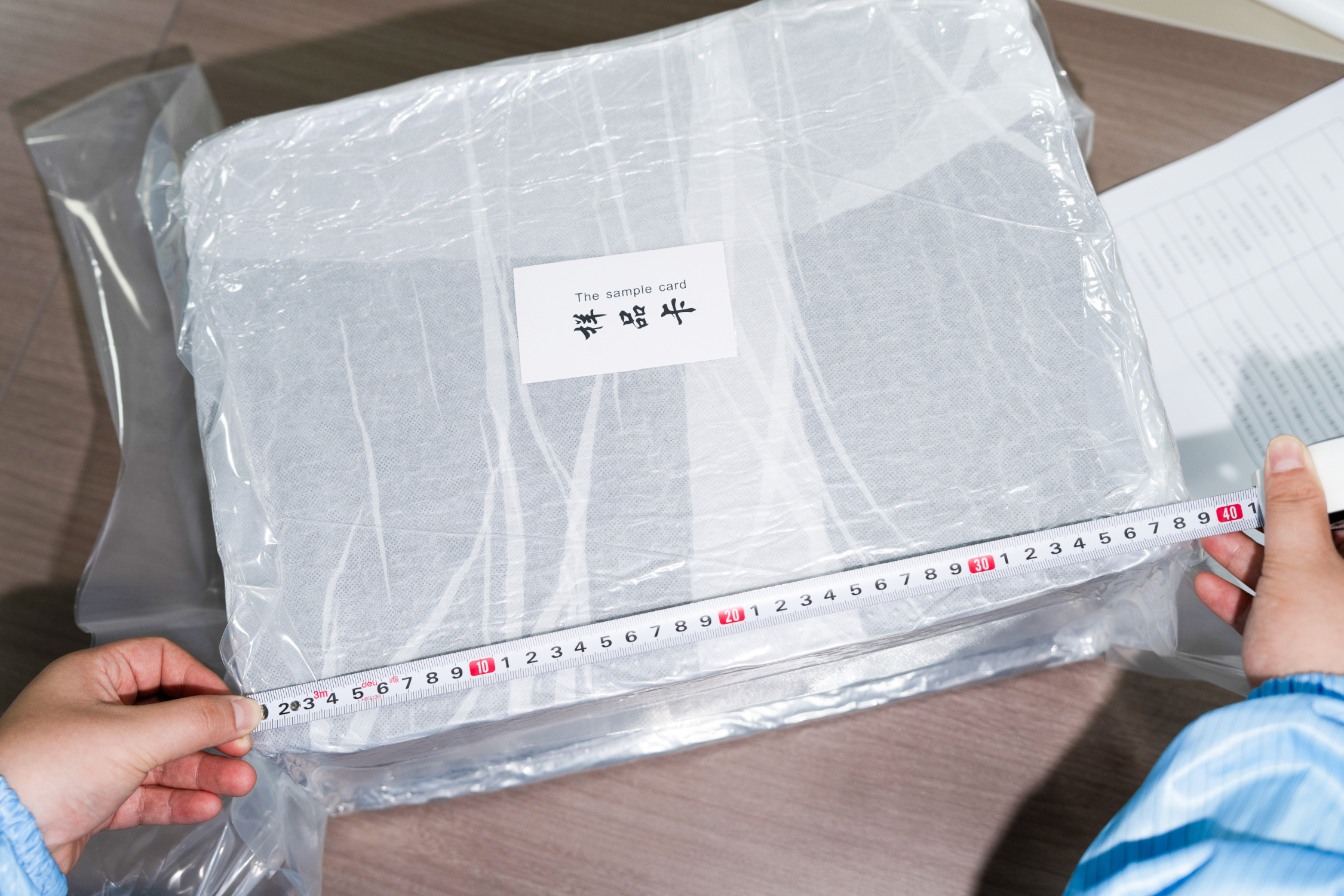

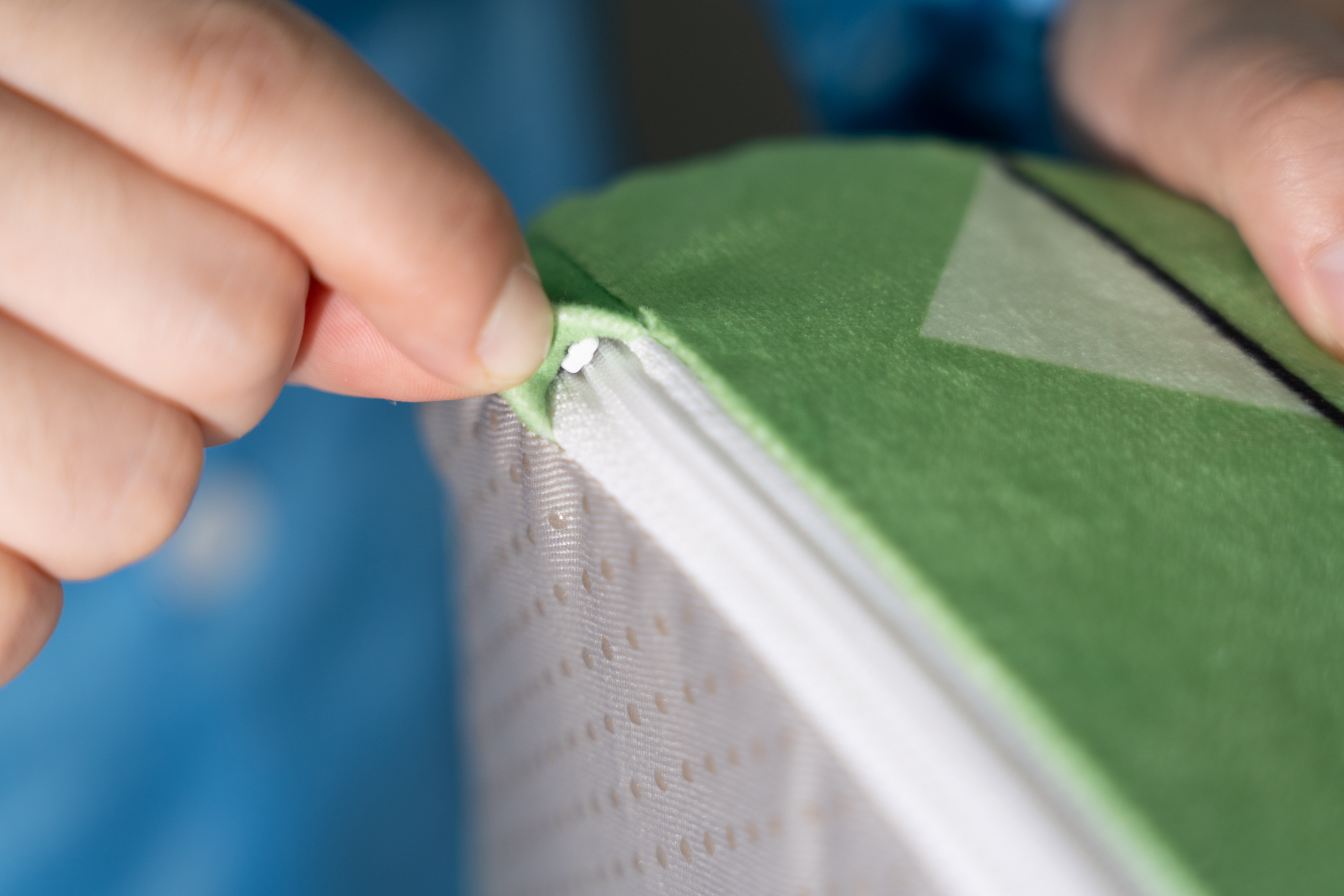

Each batch of fabric must be compared with the standard color swatch upon arrival at the factory to ensure color consistency and the absence of color deviation. Consistency in color is especially important for product sets during shipment and for matching replacement parts.