Fabric Cutting

High-precision automatic cutting machines are used to precisely cut various eco-friendly fabrics (such as glow velvet, corduroy, and teddy velvet). This ensures consistent dimensions, patterns, and clean edges.

High-precision automatic cutting machines are used to precisely cut various eco-friendly fabrics (such as glow velvet, corduroy, and teddy velvet). This ensures consistent dimensions, patterns, and clean edges.

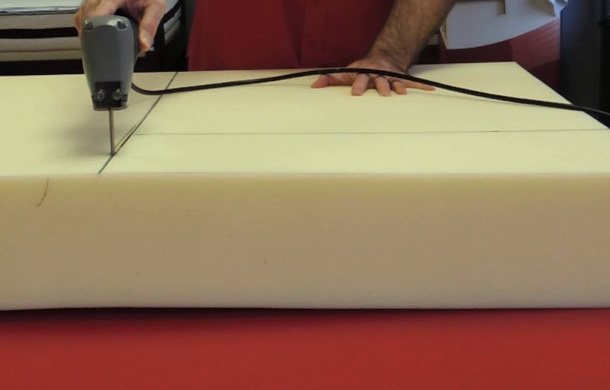

Advanced cutting equipment is employed to shape foam according to standard dimensions and custom designs, ensuring uniform filling and stable density for optimal comfort and durability.

For soft play products, specialized foams or rubber materials undergo pre-molding processes to create a perfect foundation for seamless assembly.

Thread Check:Ensuring no loose threads for a clean and refined appearance.

Durability Test:Conducting tensile tests to confirm strong and secure stitching.

Zipper Inspection:Checking smoothness and ease of operation for seamless functionality.

Foam Check:Inspecting for stains, accurate dimensions, and damages while using a density tester to ensure uniform filling.

Soft Play Testing:Conducting pressure, torsion, and modular connection stability tests to verify the product maintains its shape after repeated use.

Record the production data of each process, including raw material batch, production date, quality inspection data, etc., to ensure rapid tracing when problems arise.

Use modern information management system to track each product throughout the process to ensure product quality and customer satisfaction.

The high-precision automatic cutting machine ensures accurate fabric cutting and provides a reliable foundation for subsequent processing.

The high-precision automatic cutting machine ensures accurate fabric cutting and provides a reliable foundation for subsequent processing.

The high-precision automatic cutting machine ensures accurate fabric cutting and provides a reliable foundation for subsequent processing.

The high-precision automatic cutting machine ensures accurate fabric cutting and provides a reliable foundation for subsequent processing.

The high-precision automatic cutting machine ensures accurate fabric cutting and provides a reliable foundation for subsequent processing.

The high-precision automatic cutting machine ensures accurate fabric cutting and provides a reliable foundation for subsequent processing.

The high-precision automatic cutting machine ensures accurate fabric cutting and provides a reliable foundation for subsequent processing.

The high-precision automatic cutting machine ensures accurate fabric cutting and provides a reliable foundation for subsequent processing.