Preparation of Materials for Examination

Purpose:

Ensure design drawings, styles, fabrics, trims, and foam types are fully aligned with inventory.

Key Actions:

- Sample/Drawing Confirmation

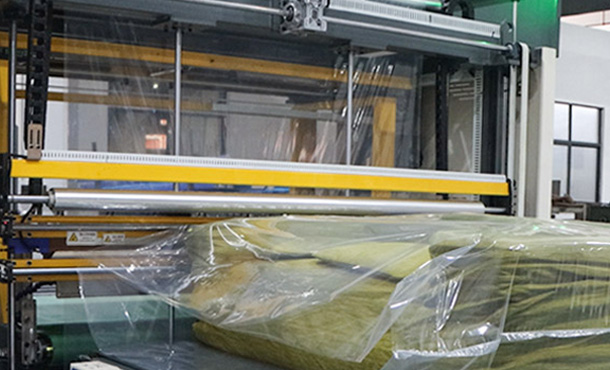

- Fabric Order

- Trimming Arrival Inspection

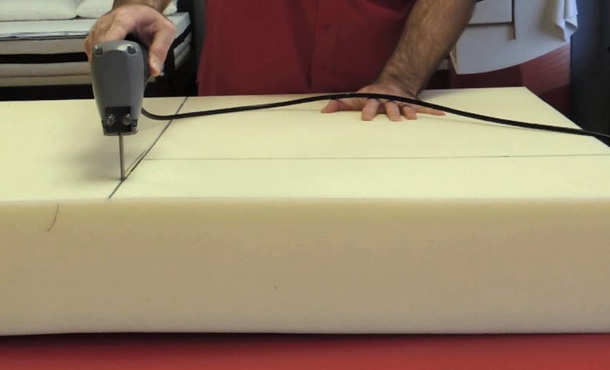

- Foam Specification Preparation

Responsibilities:

PMC + Development Department + Warehouse